Printing

| Technical Name |

Refered color |

Feature |

Example |

CMYK Printing

Offset Printing

four-color printing |

CMYK, pantone color number |

1, Use CMYK four color to present the color

2,Can be gradient color (color changing)

3, Suitable for complex artwork and tonal colors. E.g: more like a photo effect looking. |

widely used |

Spot Color Printing

Solid Color printing |

Pantone color number |

1, better printing effect in theory

2,cannot be gradient color

3,logo film setup charge is usually based on "how many colors" |

|

| Silkprinting |

CMYK, pantone color number |

usually to print simple design with less and solid colors, say, the words on label, but not print photos |

|

1, it is difficult to tell the difference by photos between "CMYK Printing" and "Spot Color Printing", but by physical sample.

2, CMYK each letter represents the color that used in offset printing – Cyan, Magenta, Yellow, Black.

| Edge |

Description |

Example |

| Metal Edge |

the logo does not cover all the metal part |

|

| color Edge |

the logo cover all the metal part |

|

Offset Printing

This computer-generated process may reproduce sophisticated multicolored photos, slides, negatives or hand drawn artwork. Original artwork and colors can be beautifully reproduced. Adding an epoxy dome will provide a durable and glossy finish. In addition, aluminum, stainless steel, and tinplate and available with or without plating.

Material: Brass/Stainless Steel/Aluminum/ZincAlloy

Standard thickness: S/S:0.7mm, 0.8mm ,1.0mm or according to customer’s requirement on thickness

Aluminum: 0.3mm , 0.7mm, or according to customer's request

Plating: None

Epoxy Coating/Resin: With or Witout

Additional Process: Laser Engraving/ Photo Engraving/ Silkscreen Printing

Attachment: Safety Pin, Butterfly Clutch, Rubber butterfly Clutch, Magnetic Disc

Standard Packing: Each piece/ poly bag

Color reference: C.M.Y.K

Steps:

Making the Negative >Artworks provided customers are used to produce films (C.M.Y.K).

Making the printing plate >Base on the firm, one Printing plate is made for each color (C.M.Y.K) in the design

Printing >One color is printed at a time by hand, before printing another color put in oven to dry.

Cutting >The metal board is cut with pins in rows, and then the individual pins are cut separately in custom outline.

Attachment >Attachment is welded on to the back of each piece.

Epoxy Coating >A clear protective epoxy coating (epoxy dome) can then be applied to the surface of your pins to protect the image fading or peeling off or getting scratched.

Final inspection >Then each pin is inspected to ensure only the highest quality is individually packaged and send for final inspection.

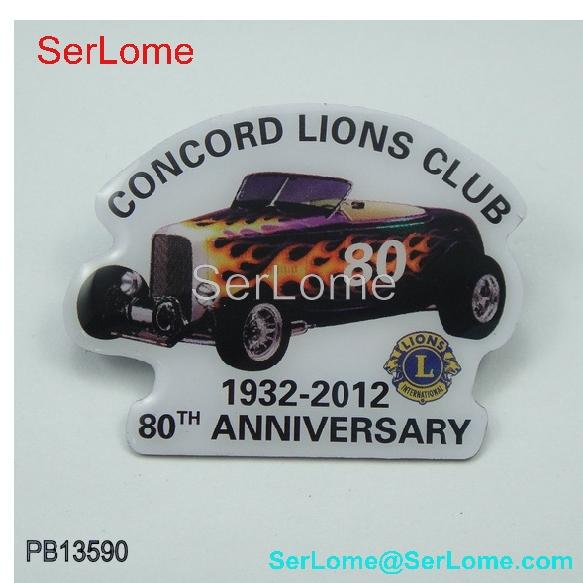

Offset Printed Lapel Pins are great for those designs which require intricate details, original design has color gradients, need to retain the integrity and fine lines of your artwork. As with Silk Screen printed pins, the image can extend to the pin edge (Full Bleed). Using the offset printed process we are able to print pictures, images and camera ready artwork using a 4-color process.